Related Videos

What is Gasification?Please install the Flash Plugin

The New Energy

Please install the Flash Plugin

Plasma Assisted Gasification

Plasma gasification is a relativity new technology that can break waste down to 1/300th of its original size by using ionized gases to produce temperatures greater than 3 times the surface temperature of the sun.

This process can safely deal with all sorts of non-hazardous and hazardous wastes through breaking down the matter into component molecules and , producing a synthesis gas (syngas) which can be used as a fuel to generate electricity, as an industrial feedstock or to produce hydrogen.

Click to enlarge.

What is plasma?

First discovered in 1879 by Sir William Crookes while conducting experiments with his Crooks tube, his discovery was initially called 'cathode rays' (electrons). The actual name for plasma however didn't come about until 1928 when Irving Langmuir compared the ionized gas to blood plasma.

Plasma is an ionized gas, which is a gas where electrons are flowing freely and giving positive or negative charges to atoms, thus making it a highly efficient conductor of electricity and generator of heat. Plasma is extremely common in the universe. Some of the many examples of plasma include lightning, St Elmo's fire nebula and the Sun. Man-made applications include plasma televisions and neon lights.

How a Plasma Assisted Gasifier Works

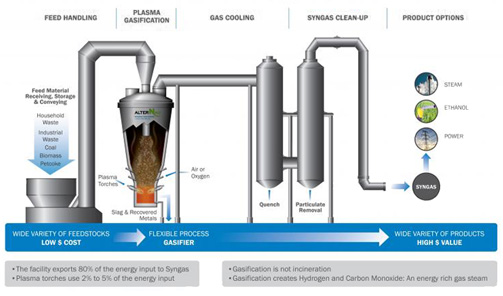

Firstly, the waste is delivered into the feed system. One of the unique characteristics of the plasma assisted gasification type waste to energy technology is its waste processing flexibility. The system can handle any combination of solid, liquid and gaseous wastes, including both hazardous and non-hazardous wastes. Solid waste is then passed through a pre-treatment process where it is shredded into smaller pieces to prevent blockages in the feed nozzle.

Click to enlarge.

The waste then is passed through an airlock which prevents gases from escaping into the atmosphere. The plasma gasifier is an insulated air-tight container with plasma torches at the base to provide the heat required to gasify the waste feed. The plasma torches consume a very small portion of the total energy available from the feedstock (2-5% of total energy input) in providing the heat required to drive the endothermic gasification process. Torch power is controlled by an automatic control system, which adjusts the gasification conditions to accommodate the potentially highly variable nature of the feedstock. Note that the plasma arc is contained within the body of the plasma torch, and therefore, the waste material is not directly subjected to the plasma arc and the associated extreme temperatures. Hence, the classification of the process as plasma assisted gasification. Nonetheless, the plasma torches facilitate operating temperatures above typical flame temperatures associated with combustion of the waste feedstocks and also in excess of the melting points of metals and inorganic materials. Either air or oxygen and/or steam is injected above the torches to provide a source of oxygen for the gasification process. Importantly, the gasification occurs in an oxygen starved environment, such that a combustible syngas product is produced, rather than a non-combustible flue gas, which would be the case if all the feed material was combusted.

Inside the gasifier any carbon based, or organic molecules become volatilized and is turned into synthesis gas (syngas), which is a mixture of hydrogen, carbon monoxide and carbon dioxide. Inorganic compounds will become vitrified, or melted down and converted into an obsidian like substance and metals will melt down into a form of slag. An overflow mechanism is used to control the amount of slag available in the chamber at all times, ensuring that enough is left to maintain these high temperatures. Utilising this process a plasma gasifier can deal with almost any kind of waste, including municipal solid waste and hazardous wastes.

After leaving the gasifier chamber the syngas passes through a series of filtration systems where it is cooled by using water injection and is filtered of all particulate matter (which can then be fed back into the plasma gasifier). The cooling process acts to prevent the formation of dioxins and furans as these undesirable compounds are known to form within a specific temperature range. The gas will then be reheated to create a series of catalytic reductions to reduce the amount of NOx and convert it into atmospheric nitrogen and water. A series of scrubbers will then remove any acids, chlorides, fluorides, sulphates, phosphates, sodium and calcium.

A turbine can be connected to the process to generate electricity, which can be used to not only power the plant, but provide an alternate clean source of renewable power to the community.

Recoverable commodities

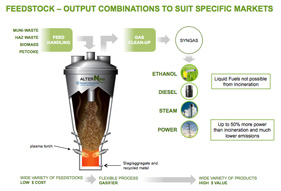

Outside the electricity generated by a plasma convertor, there are two main commodities that can be recovered, the individual amounts of which depends on the type of waste being feed into the convertor.

Synthesis gas (syngas), the main output of the plasma gasifier, can be used as a fuel source in power plants, or treated further to generate hydrogen. It can also be used in the rural and industrial sector in the production of a wide range of polymers, chemicals, biofuels (including ethanol), fertilizers, pressure agents and more.

Slag is the name given to the solid product produced from a plasma gasifier, and depending upon how it is cooled; the slag can create several types of commodities. These include an obsidian-like silicate material which can be used in concrete or asphalt, even shaped into bricks or pavement stones for use in the construction industry or even be used in the abrasives industry. Metals can also be extracted and on sold to various industries.

Rock wool can also be produced from the slag; this commodity is a highly efficient insulator with higher energy efficiencies than fibre glass, it is highly absorbent and lighter than water, with many potential methods of use in both the industrial and environmental segments.